On an ordinary visit to Jeffrey Brand’s house, it would not be unusual to find displayed in his dining room a single, French Blue-colored shoe with an intricate pattern on its side. What would seem out of place in most homes is, at the Brand house, art — tasty, edible art.

The shoe, it turns out, is a cake.

Brand, a Marquette Business instructor of practice in management and the director of graduate studies, is no ordinary baker — he specializes in so-called “illusion cakes.” Put simply, these are confections designed to look like something else.

Take a baseball, for example. The sort of cake you might pick up from a bakery might have white buttercream and narrow lines of red frosting applied through a piping bag to resemble the ball’s stitches. Nevertheless, it’s merely a representative shape atop an ordinary sheet cake.

Brand’s baseball cake mimics a baseball in almost every way: spherical, firm to the touch, with raised stitches trimmed with a serrated knife to lay uniformly atop the frosting. At a glance, one might assume it was a sculpture.

Brand got his start like many modern hobbyists: the internet.

“I like to watch random YouTube videos, and a few years ago, I came across a video about how to make these illusion cakes,” Brand says. “I decided that I really wanted to see if I could pull it off.”

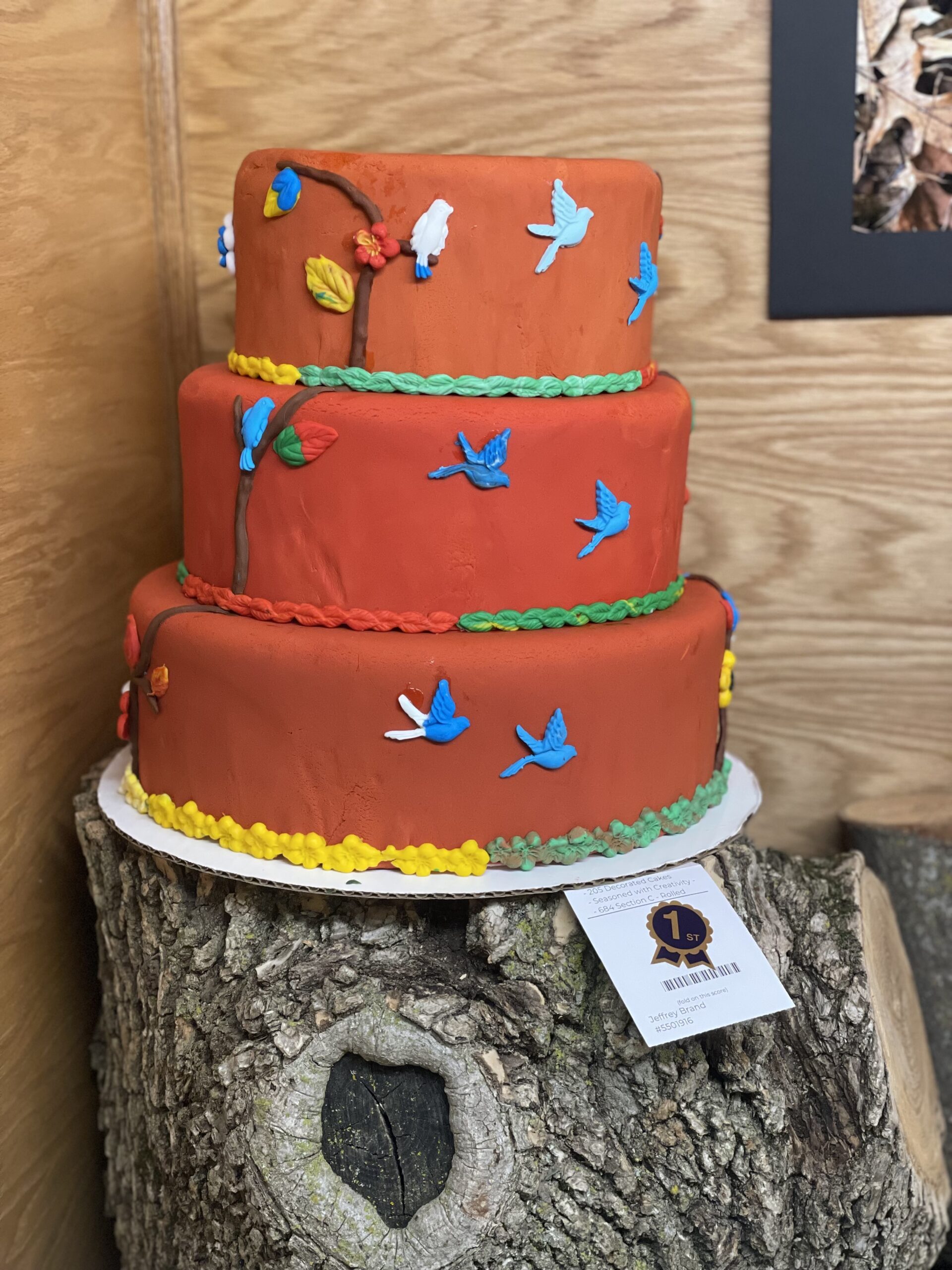

Years later, Brand has pulled many of them off, including several Wisconsin State Fair prize winners. He has made panda heads, pool tables, company logos, Easter baskets and Christmas sweaters — all lifelike and just as edible.

Prior to his teaching career, and before he took up baking, Brand spent more than 25 years in the supply chain business, most recently at Harley-Davidson, where he managed product development and production line issues. To a supply chain professional like Brand, there’s a lot more of a relationship between making motorcycles and making cakes than meets the eye.

“Supply chain is design, sourcing, manufacturing and delivery,” Brand says. “That’s what I teach in my class. Every time I do a new cake, I have to go through all four of those steps.

I have to figure out where to buy all of this stuff: black fondant, orange fondant, special supplies. How do I make a cake that I’ve never made before? Do I have everything I need? That’s what you have to figure out in operations, too.”

Each step of this process was on display for one of Brand’s most acclaimed creations: the basketball cake.

“I had a few basketball players in my class, and I announced at the start of the semester that I was going to make them a basketball cake, but I actually had no idea how to make it,” Brand says.

One thing he did know from his supply chain days was how to make a basketball: form the core of the ball from black butyl rubber, cut the leather strips for the covering, make incisions in between those strips for the grooves. He showed his class the process and promised he would make the cake the same way.

It didn’t go as planned right away.

Brand made a model of his cake, spent hours sculpting a confectionary creation to match, put it in the oven and was soon rewarded with a melted, runny puddle that more resembled a deflated basketball.

“Every cake I make has started out with a disaster,” says Brand, who estimates he’s thrown away at least 30 cakes that haven’t turned out to his standards. “The basketball cake I had to make three times.”

“All the cakes I make are educational,” he emphasizes. “I’m always thinking about how you might make something in a factory: start with a design, create a process and execute it. This is the same kind of thing I teach in class — designing sound processes to deliver a product.”

Not content to let his hoop dreams fall flat, Brand found the flaw in his basketball cake process: an interior cooking more slowly than its surrounding structure. He solved the

problem by sticking an upward-facing nail to the bottom of the pan and setting the cake on it. The nail conducted heat into the core, warming it more evenly with the rest of the cake.

This is the same kind of problem-solving capacity Brand hopes to instill in his students. His Manufacturing, Planning and Control class was the first in Marquette Business to use the Omron Advanced Automation Lab, which gives students access to industry-standard robots and other automation technology. During that class, Brand makes sure everyone innovates on the fly.

“We rig the robots so that they don’t work perfectly, and then I tell my students, ‘This is going to happen in the real world, and you’ve got to figure out a solution,’” Brand says. “Let’s say the problem is that the robotic arm isn’t attaching correctly. Propose some ideas. Test some of those ideas out. You do that for long enough, you’ll find the solution and make it work.”

Even though Brand has ribbons at the state fair and rave cake reviews from the Marquette basketball team, he still has not climbed his dessert Mount Everest: a cake shaped like a pair of Nike shoes.

“The whole reason I wanted to get into illusion cakes was to make a basketball shoe and I’ve still never done it,” Brand laments. “I’ve been making cakes for four years and my original reason for doing this still hasn’t been achieved.”

Progress is imminent, though. Walk-on basketball player Jake Ciardo lent a pair of his shoes so Brand could take measurements, the first step in what will eventually be the Marquette Cake Boss’ proudest pastry accomplishment.

And when it’s done and admirers ask how he did it, he’ll undoubtedly say it was no piece of cake.