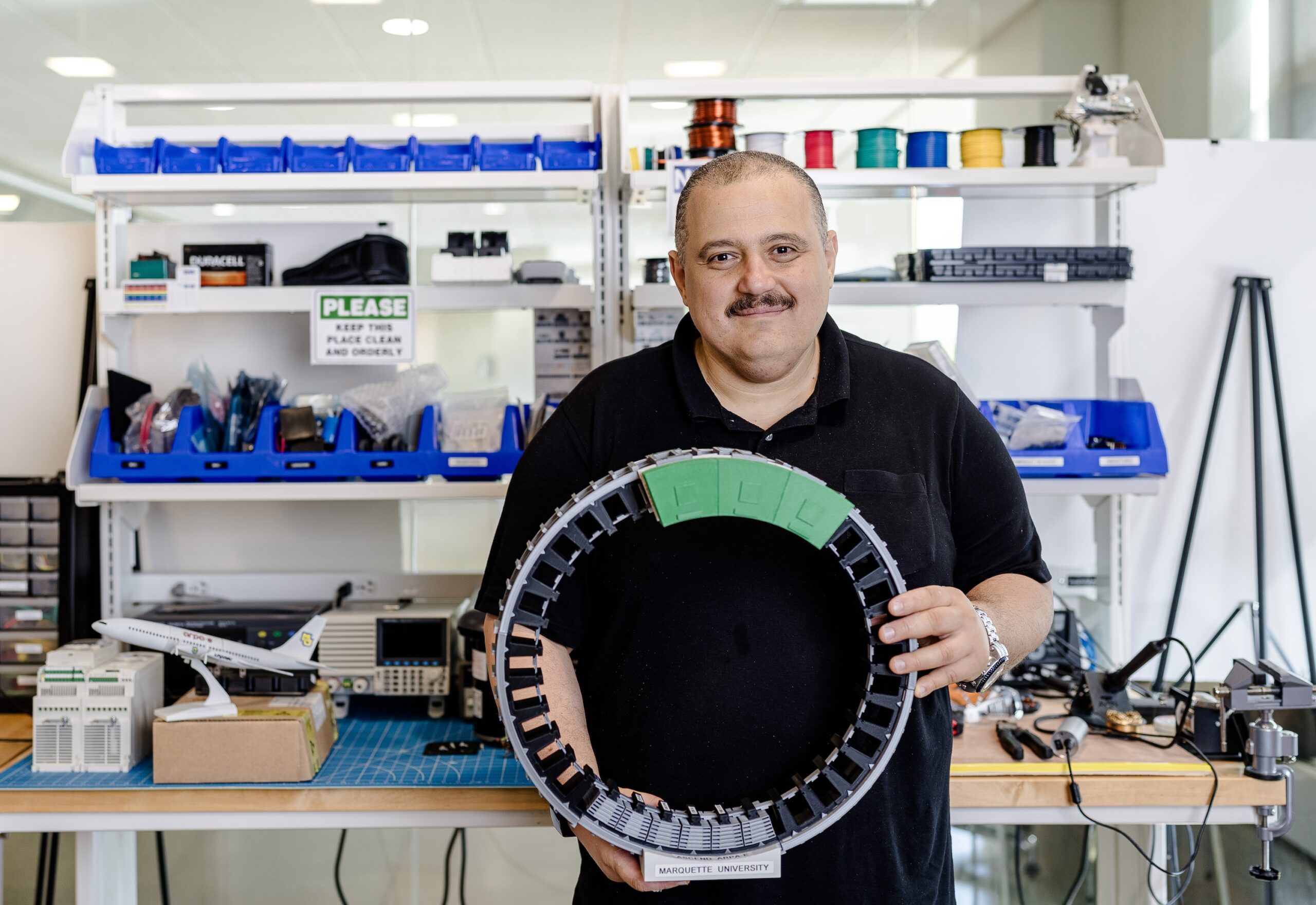

A white model plane emblazoned with the logos of Marquette and other partners sits in the Werner Sustainable Energy Lab in the Opus College of Engineering — a vision of the future. Nearby, Dr. Ayman EL-Refaie, Werner Endowed Chair of Secure and Sustainable Energy Systems and professor of electrical and computer engineering, and his faculty and student partners work fervently to help that vision of electric-powered and hybrid aircraft take flight.

“What we’re trying to do with planes today is what has been happening with cars,” EL-Refaie explains. “So, for larger planes, we’re trying to come up with hybrid models where you have the jet engine and then a bunch of electric motor-driving propellers. For smaller planes, we are trying to go pure electric.”

It’s one of many ways that research teams across the nation are working to help the United States reach an ambitious goal of net-zero emissions by 2050. Last year, the Marquette-led team advanced to the second phase of a highly competitive project overseen by the U.S. Department of Energy, qualifying for a total of $5.6 million in agency support. Marquette and Texas A&M were the only universities to advance after the proof-of-concept phase — the other five teams selected were from industry giants such as GE and Honeywell.

“It’s very unusual for a university, especially one the size of Marquette, to be leading a project like this. … Usually a big company would be leading and a university like us might be in a support role.”

Dr. Ayman EL Refais on the project

The Marquette team — co-piloted by Dr. Nathan Weise, associate professor of electrical and computer engineering — is now working on key components with hopes of having a prototype ready to test this fall at the Connecticut headquarters of RTX Technology Research Center, a leader in aerospace and defense.

“It’s very unusual for a university, especially one the size of Marquette, to be leading a project like this,” EL-Refaie says. “These are the types of projects that usually a big company would be leading and a university like us might be in a support role. Just the fact that we made it this far is a huge, huge deal.”

That also means big opportunities for Marquette students. “Even though it’s difficult at times, I think it’s good that our students get full exposure to everything — not only the technical aspects, but also seeing the logistics and the reviews and how a project of this magnitude works,” he says. “It’s good training for real life.”

One challenge has been how to reduce the mass of the electric motor while producing sufficient power — and managing the heat output at the same time. “Everything has to be two to three times lighter than the best in class today,” EL-Refaie explains. “To reduce the size of electric motors, we’ve been looking at advanced cooling, new manufacturing processes, and more integration between the motor and the power electronics.”

As the team resolves one challenge, a fresh one emerges. Still, they’re making progress. Many startup companies are also working to electrify smaller planes, whether for carrying packages or taxiing a few passengers. If Marquette’s prototype is successful, the next step would likely be to license the technology to another company or adapt the Marquette system for a company’s specific needs.

EL-Refaie predicts that electric-powered small planes might be ready to hit the skies in five to 10 years. Because of their larger size and additional regulation, hybrid commercial planes will likely require a longer development runway, though they have the potential to reduce fossil fuel consumption by 20 percent or more compared with conventional aircraft.

Marquette’s electric mobility expert is improving vehicles on the ground, too. With support from another $5 million U.S. Department of Energy grant, EL-Refaie is developing electric drivetrain systems that incorporate iron nitride magnets free of rare earth minerals, which have become increasingly expensive. His industry partner, Niron Magnetics, has raised millions of additional dollars from government grants and investors, and Time magazine declared its Clean Earth Magnet among the best inventions of 2023.

EL-Refaie says that both efforts are “dream projects,” though it’s grueling to pursue both at once. However, the payoff for the environment could be worth it. “These two topics — the hybridization and electrification of aerospace and eliminating or reducing rare earth materials — are two of the most critical topics globally,” he says. “It speaks volumes that Marquette is working in these areas and that we have partners of this caliber.”