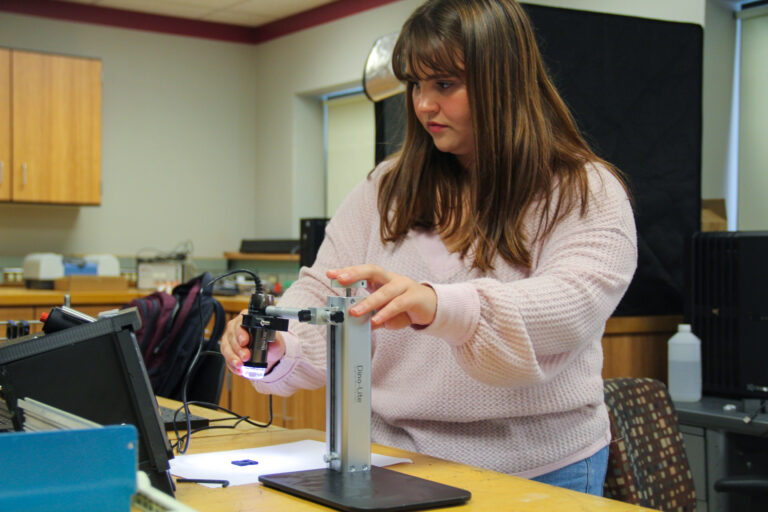

It’s been six months since the Omron Advanced Automation Lab opened in the Opus College of Engineering, and Dr. Phil Voglewede, professor and associate chair of mechanical engineering and director of the lab, says it’s all a dream come true.

Established with a $1 million-plus gift from Omron Corporation, the lab opened in March of 2023 on the fourth floor of Engineering Hall with the hopes of further strengthening the connection between engineering and business by combining innovative industrial automation and robotics technology with supply chain platforms — and that’s exactly what’s happening.

Voglewede is responsible for making sure the lab is used to its fullest capacity and admits that opening this space has fulfilled his vision of educating the next generation of engineers.

“I really wanted to create a place where students can learn to fail. It was wonderful to have it all come together this spring. Since then, I have been working on getting more students into the lab,” Voglewede says.

Synergy in action

The creation of the Omron Lab has been a team effort, with college and corporate partnerships working hand in hand. Although the state-of-the-art lab is housed in the Opus College of Engineering, there’s been a concerted effort to give multiple colleges access to it.

“If the lab is only used by engineers, it will fall short of its goal of learning from failure,” Voglewede says. “Many automation systems fail due to not understanding how it fits into business through operations management and supply chain. One can engineer the best automation system, but if the parts are not in the right place at the right time, the system will be a waste.”

That’s why the lab has partnered with a College of Business Administration operations management class. Dr. Marko Bastl, director of the Center for Supply Chain Management and associate professor of supply chain management, says the cross-college collaboration is gaining momentum.

“Mr. Jeff Brand, full-time instructor and director of the supply chain management program, developed a fantastic business game as part of manufacturing planning and control class. Supply chain students had to develop an end-to-end manufacturing process for producing a simple product,” Bastl explains. “As part of this game, Dr. Phil Voglewede’s engineering students worked together with supply chain students on programming the robots in the lab to construct a manufacturing line. They developed various configurations and learned among others about the justification of automating traditional manufacturing processes. It has been really well received by our students and it is another step towards the increase of applied learning in our colleges.”

And it’s not just the colleges that have benefited from the lab’s latest addition. Dr. Carmel Ruffolo, associate vice president of corporate engagement in the Office of University Relations, says the Omron Lab is an important opportunity to cultivate valuable partnerships with Marquette.

“I’ve worked with many corporations and organizations during my career. This has enabled me to bring many opportunities to campus to benefit our students, faculty and staff,” Ruffolo says. “The Omron Lab is one of the best examples of this. The lab has enabled us to give our student’s state-of-the-art technology and provide our other corporate partners a space to ‘test out’ automation.”

Classes and future endeavors

The Omron Lab provides the opportunity to educate students on the cross-section of business and engineering disciplines — all while an integrated physical space makes it happen.

“The lab is a vehicle for us to broaden students’ horizons about the importance of automation and collaboration between engineering and supply chain fields, by learning through failures — which is a very impactful and rewarding approach to learning,” Bastl says.

The first supply chain class that was offered and that integrates the lab’s offering is Manufacturing, Planning and Control. Other supply chain classes planned in the future are Quality and Process Control and Applied Lean Six Sigma.

“At the end of the spring semester, we had some freshman engineering classes programming the robots, the operations management class learning about automation, and an upper-level engineering class interacting with motor and drives to understand control parameters. This past summer we have been further perfecting these experiences and specifying the equipment for year two,” Voglewede says.

As for what to expect down the road, Voglewede predicts constant transformations.

“In 10 to 20 years, I envision the lab to be in flux — just as it is today. I envision a lab that is always changing and adapting to the technology that is driving automation,” Voglewede says. “I envision a lab where students in all disciplines and levels can grapple with the failure that these old and new technologies summon us to understand.”