By Dr. Doug Fisher, associate professor emeritus of practice; retired director of the Center for Supply Chain Management

A month ago, and for a few years prior, I thought times were really interesting and exciting. Changes in the geopolitical landscape (U.S.-China relations) were already forcing companies to rethink their global supply chains, the emerging digital ecosystem was enabling companies to totally rethink portions of their supply chains (manufacturing, distribution, inventory management, product design, etc.), digital-savvy talent was in high demand, and a strong economy enabled heads-up thinking and positive attitudes.

What a difference 30 days make.

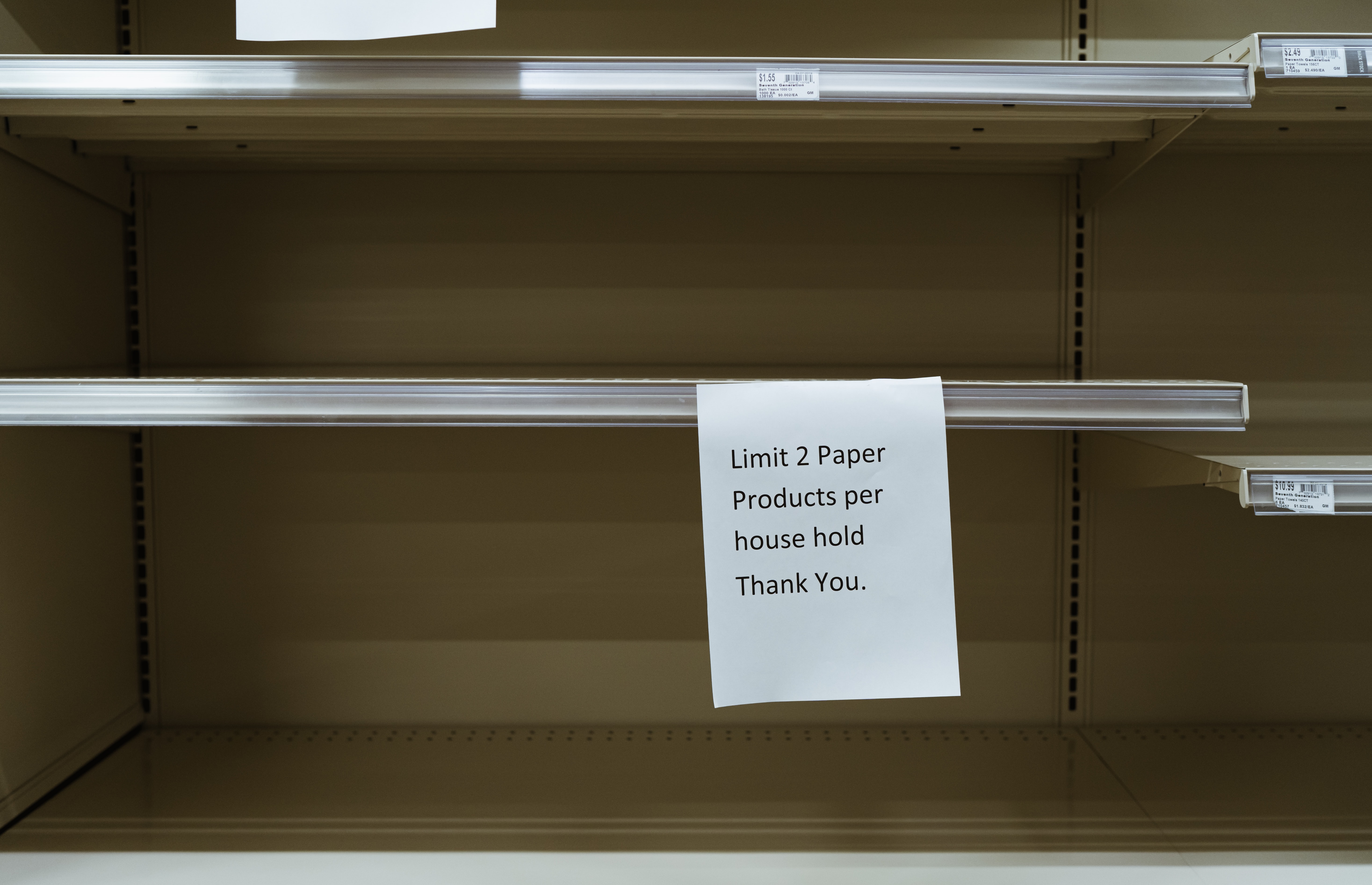

Broad-scale “social distancing” has triggered business, school, church and sports events closings (and now all non-essential activities); market sell-offs triggered circuit breakers; global disruptions replaced election headlines in every newscast; there have been significant personal and personnel disruptions; and there are massive government infusions of programs and funds. And I have no idea what is going on with toilet paper. (Though here is some interesting reading for those who want more information.)

This “thing” hit at staggering scale and speed and the impact on every supply chain is different: retail versus food versus automotive versus electronics versus chemicals versus medical versus manufacturing versus services versus … toilet paper. And, every company’s supply chain organization is different — from huge staffs to one-armed-and-legged paper-hangers; comprehensive organizations covering procurement, manufacturing/operations, inventory, distribution, and customer service; to siloed functions covering distribution only.

What follows is a list of considerations I’ve compiled from watching companies contend with this new environment. I’ve added some comments (in quotes) that I have been hearing from colleagues in the field:

- Get prepared. Set up a “war room” (virtual or real) to contend with and coordinate wide-ranging issues — including supply chain. This group can coordinate communication to suppliers, logistics companies, employees, customers, financial institutions, shareholders, among others, and coordinate work rules, travel rules, pay rules, etc. If resources are scarce, elevate some of your experts “on the shop floor” to help.

- “War room mentality around securing components and increasing manufacturing capacity for the surge in demand on products.”

- Be informed. Set up real-time communication with the Centers for Disease Control, the World Health Organization and the Department of State.

- “Our industry group has had two calls with the White House asking for a number of us to retool/support production of surface disinfectants, sanitizers and PPE [personal protective equipment].”

- Take stock. Assess supply chain vulnerabilities quickly: suppliers in your network, transport providers (global container operations and air cargo capacity will be disrupted both now and when things recover), financial capacity (yours and theirs), product complexity, organizational depth and strength, and distributors.

- “Distributors are putting updates on their websites daily for customers. It’s important for their digital media to reflect their stance on business, allocation efforts, extend delivery times, etc.”

- “Our manufacturing sites are separating the shifts by one hour between them to sanitize the common areas and also workstations.”

- “In addition to that, we are also redistributing the number of associates per shift and line trying to reduce contact among them.”

- “We’re looking at our IT capabilities to ensure that our servers can handle the workload for the offsite folks, which includes rerouting customer calls to agents that are working from home.”

- Prioritize: Plan to operate to manage cash flow. Cash is always important but in times of high risk, those with the cash get to stay in the game. Both your firm’s finances and your personal finances cannot survive without it. Those with strong balance sheets can even use these times to build their company – new customers, new employees, new technology, new products, new markets, etc.

- Anticipate. Review each vulnerability for backups/alternatives, delays, days’ inventory, and capacity. Pre-Chinese New Year shipments have arrived and it is unlikely more will arrive quickly.

- Review and estimate demand. While it is not apparent from its name, supply chain is demand-driven – no demand, no chain. We’ll begin to recover when demand recovers.

- “We’re modeling revenue impact as we expect this to hit through May and part of June. Every day it changes.”

- Review your customer base. If you need to prioritize or ration, you will need a priority plan. This is very tricky and will require thoughtful communication.

- “We’re doing a deep dive into market data to evaluate where our business is exposed. Distributors are starting to extend payments. Additionally, we are looking at market segments that are closing. For example, restaurants and bars, and then evaluating the impact.”

- “Our smaller customers are asking for extended terms to pay bills. They service the restaurants, theaters, etc. (that are being asked to close).”

- “Our larger customers are dealing with unprecedented demand for sanitizers, toilet paper, etc. There are shortages everywhere and the distributors are putting customers on allocation. They’ve already prioritized hospitals and long-term care facilities.”

- “Most of our customers aren’t accepting appointments. Everything is teleconference.”

- Review your supply chain. If your supply is dependent on specific countries, consult directly with locals. They are likely better sources than media and government sources.

- Review and estimate demand. While it is not apparent from its name, supply chain is demand-driven – no demand, no chain. We’ll begin to recover when demand recovers.

- Modify. Localize inventory when possible near your manufacturing operations or near your markets.

- Communicate — externally. Increase visibility into every supplier, distributor and node in your supply chain with electronic visibility, daily phone calls, daily text messages, etc.

- Communicate — internally. Debrief frequently — not only to fix daily problems in real time, but to build enterprise-wide knowledge for the recovery and future disruptions.

- Learn. Use the pain of these disruptions to educate your supply chain organization not only on what it will take to survive this and recover, but also on the strategic digital options possible in the future.

We will come out of this. The world has survived pandemics/epidemics in the past and of much longer duration (often decades).

As we return to normal (or whatever the new normal may be), let’s recognize the road may be bumpy. There is a concept in supply chain management called the “bull whip effect:” small changes in demand can cause major swings upstream in the supply chain.

For example: the run on toilet paper causes shortages, which causes stores to order much more. Manufacturers of toilet paper monitor these increasing demand signals and ramp up production. As production catches up to higher “perceived” demand and toilet paper hits the shelves, we find out that customers have a year’s supply of toilet paper and aren’t buying any more. Stores drop future orders. Manufacturers drop production. And, back and forth we swing until things settle out.

The process to emerge from this will be easier to manage if companies have gone through some version of the considerations listed above.

If you like challenges, this is a great time to be in supply chain management — though I prefer the pre-COVID-19 atmosphere.